Climate change, its consequences and ways of minimizing CO2 emissions have been a focus of science and technology for decades now. One aspect of climate impact research at our university is the operation of the FACE experiment (Free Air Carbon Dioxide Enrichment). This project investigates the consequences of an atmospheric CO2 enrichment by 20% on plant growth, product quality, soil processes and interactions between plants and parasites. Often visitors who take part in campus tours or talks at our university ask the question (mostly tongue-in-cheek!) whether we are relying on noticeable quantities of CO2 being emitted (2017: 210 tons of CO2) for our project – and, therefore, even are contributing to climate change?

Although CO2 would have been emitted to the atmosphere even without taking the detour via our FACE plant, this is a justified question which provided the starting point and driver for our "FACEing Compensation" project. We now investigate how CO2 emissions can be reduced or offset at our university. Within the scope of the project "CO2 Neutral State Administration" presented on the occasion of the Sustainability Conference, the federal state of Hesse decided to become carbon neutral by 2030. This will be realized in 3 steps: minimizing the energy demand (1st part), substituting fossil fuels (2nd part) and managing indispensable emissions by means of emissions credits (3rd part). Referring to the 3rd part, the "FACEing Compensation" project even goes beyond this target: it is investigated in which way the university, using its facilities and special conditions and without being dependent on buying CO2 credits, which are subject to price fluctuations, can compensate for unavoidable CO2 emissions through converting carbon based biomass (C) into a stable form, such as products or soil. This concept idea was acknowledged as part of an initiative of the Hesse Ministry of Science and Art (HMWK) and is now further progressed as an „example case“ for HGU.

Due to the agricultural use of the land belonging to the university, there is a higher potential for obtaining residual biomass compared to other institutions in Hesse. Whilst CO2 is converted from the atmosphere through the process of photosynthesis, the fermentation or combustion of biomass in turn releases CO2 to the environment. In order to achieve the goal of 2°C or even 1.5°C set in the Paris Climate Agreement it is not only required to reduce CO2 emissions but also to extract CO2 from the atmosphere. Therefore, in order to become carbon net negative it is imperative to avoid emitting CO2, following the production of biomass and the cycle of photosynthesis.

The only known industrial approach to make this work so far is called Carbon Capture and Storage (CCS). During this process CO2 is separated, i.e. captured, from exhaust vents from combustion of coal or biomass and is subsequently compressed and stored in geological storage areas. This would in turn make the combustion of fossil fuels carbon neutral, while combustion of biomass would be net negative, i.e. extract CO2 from the environment. However, due to unanswered questions regarding transport, storage and, in the case of biomass, the parallel demand of space for crops production, the concept of BECCS (Bio Energy CCS) has not established yet. Furthermore, it is a cost intensive process which does not add any economic value.

The product of pyrolysis that bonds CO2–C is called biochar which is not only a stable form of carbon in the long run, but can also serve as emission credits. Opposed to CCS, biochar has multiple environmental and economical applications. Optimized with best available technology, this concept which has been used for centuries, produces high quality and long lasting biochar (at respective process temperatures, from several 100s to 1000 years if embedded into the ground). The application of the product is very versatile and ranges from agriculture (manufacturing of fertilisers and livestock farming) to construction industry and waste water treatment as well as manufacturing of filtration devices and electrical capacitors, the latter currently seeing a significant focus in terms of research and development.

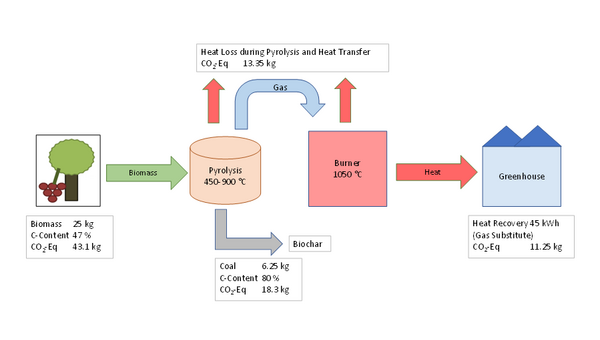

In order to manufacture biochar, which is long-term resistant to decomposition, from waste biomass, an oxygen deficient environment between 450 to 900°C is required. In this process, macromolecules, such as lignin or cellulose, are thermally converted into a flammable gas phase. Inorganic matter (minerals) as well as the majority of carbon, however, are converted into an ordered, aromatic lattice structure. The flammable gas phase can be converted into an oil based biofuel via a condensation process or directly burnt for heat generation.

This provides opportunity for dual use of this technology at our university. The generated heat covers the heating demand of our greenhouses, partly substituting currently used natural gas. At the same time, a carbon rich product is manufactured which extracts CO2 from the environment as long as it is not used in an oxidation process, releasing CO2 again.

The first steps of this project were estimating the energy requirements to heat the greenhouses as well as investigating the potential supply of wooden-based biomass on the perimeter of our university. This required a concept to identify the most important points for measuring energy demand, followed by the installation of measuring devices. The measured energy requirements to heat the greenhouses exceeded any anticipations: For the last heating period around 1,500 MWh, 363t CO2 equivalents were used which represents around 20% of the total heating requirement of the university. In comparison, a typical mid-range car (130 g CO2/km) could travel up to 2.8 million kilometers, 7 times the distance to the moon, until the equivalent amount of CO2 is emitted.

Estimating the capacity of biomass started with the process of entering data into ArcGIS, a database for capturing yield data relating to viticulture, fruit production as well as green spaces. This provides information on the total wood biomass production for each area which is the basis for the operation of a pyrolysis production plant. Depending on the scenario this can be between 150 and 220 tons of woody biomass.

The former analysis answers two key questions: (1) The university has the supply of biomass required for operating a pyrolysis plant and (2) also the demand for the generated heat. Through the conversion of biomass about 183t of CO2 could be extracted from the atmosphere per year and be converted into a long-term stable form, compensating for half of the current energy demand for heating our greenhouses. We are now working on building a model that compares various pyrolysis plants, optimizes the operation of the process and exactly quantifies mass flow streams. The graphic below illustrates a flow diagram including mass flows and respective CO2 equivalents based on 25 kg of biomass. The generated model will provide a flexible basis for making a decision regarding the procurement of such a pyrolysis plant for our university.

As there can be conflicts with existing processes when using branch and vine pruning waste, further sources of biomass within the region are evaluated. In such cases, the pyrolysis plant of our university could produce local emission credits. Within the second half of this year, the currently developed prototype will be further amended to process additional feedstock and assess their potential. This information will feed into a Carbon Footprint Analysis in 2019 which will conclude this project.

Pyrolysis and the production of biochar from residual biomass will not provide the only solution to extract CO2 from the atmosphere and, consequently, to slow down climate change and its significant impacts. However, it is the only readily available and proven technology which does not only substitute fossil fuels (decarbonization), but is also carbon net negative, i.e. extracts CO2 from the atmosphere.

At this point we would like to say a special "thank you" to all colleagues from Infrastructure and Park Maintenance, to the heads and employees working in the Departments of Viticulture, Pomology and Vegetable Crops as well as to all colleagues from Landscape Architecture of the Department of Soil Science and Plant Nutrition for their valuable support when collecting the data.